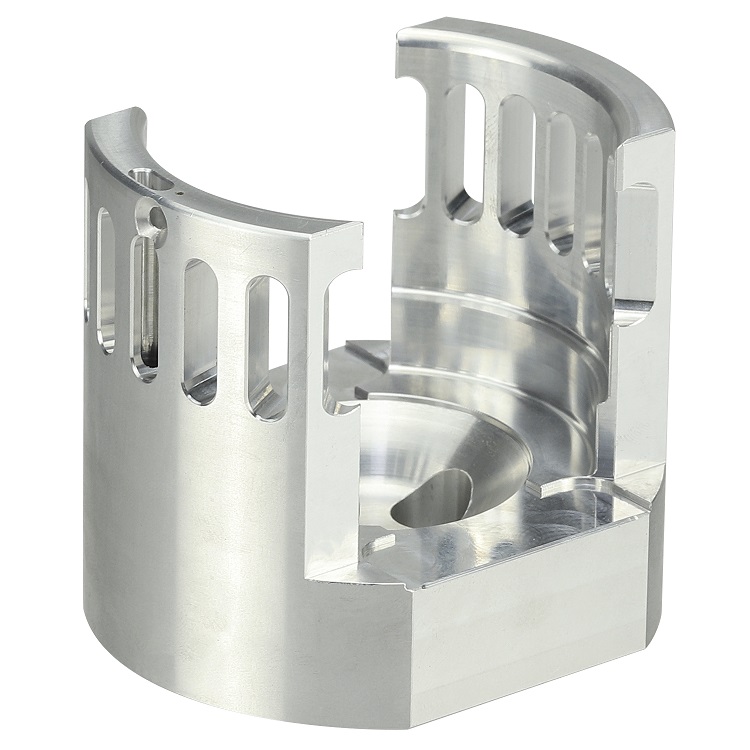

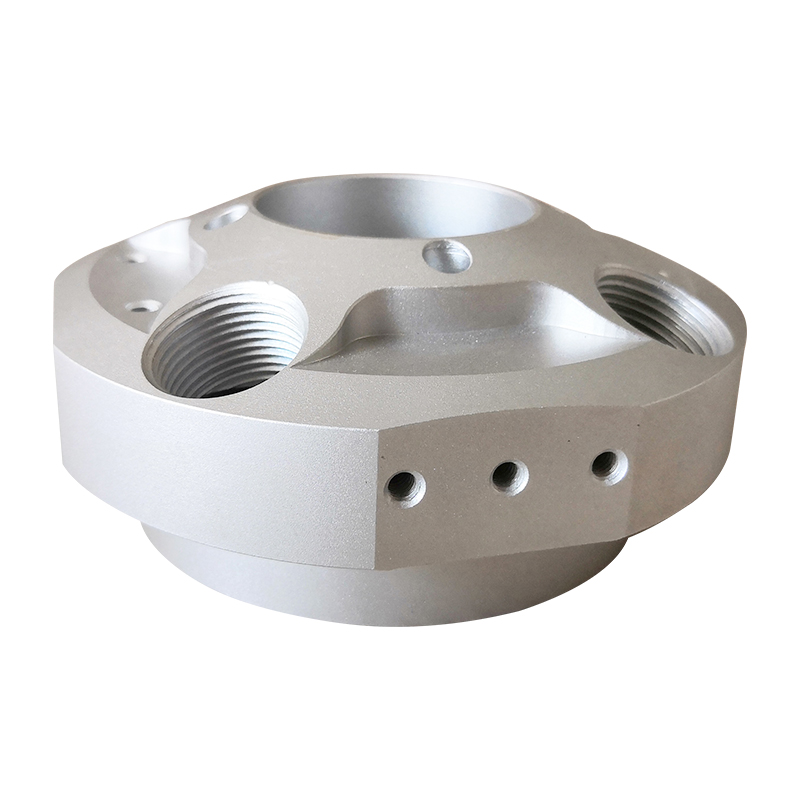

Aerospace Parts

Process characteristics of CNC machine tools for five-axis machining of aerospace parts

Modern aerospace product parts, in order to reduce the weight of the aircraft, increase the maneuverability, payload and range of the aircraft, modern aircraft have been lightweight designed, and high-strength new lightweight materials are widely used. In order to improve the strength and reliability of the parts, the overall blank parts and the thin-walled overall frame structure are mainly used. In addition to a large number of aluminum alloys, titanium alloys, high-temperature resistant alloys, high-strength steels, composite materials and engineering materials are also widely used for parts materials. Difficult-to-machine materials such as ceramics.

For this requirement, the process characteristics of five-axis machining of aerospace parts have the following seven points:

1. The specifications, sizes and structures of various parts are very different, and the process equipment such as five-axis machining machine tools for aerospace parts is not highly versatile. For example, high-rigidity, high-efficiency, large-scale, and high-speed machine tools are required for processing airframe structural parts, precision and flexible precision machine tools are required for processing key engine parts, and multifunctional five-axis compound machine tools are required for processing airborne equipment parts.

2. The modern aviation manufacturing industry is usually faced with production tasks of multiple varieties, small batches, and short production cycles, so the five-axis CNC machining process system is required to have a high response speed.

3. The structure of the product parts is complex, and the five-axis machining is difficult. The shape of the parts involves the shape of the fuselage, the shape of the wing, the fusion area of the wing and the body, etc. Most of the parts are related to the aerodynamic shape of the aircraft, and there are complex assembly coordination relationships between the peripheral contour and other parts.

4. The machining volume of five-axis parts is large. Due to the increasing use of overall structural design, the number of parts that need to be cut has increased significantly, and most of the parts have a very large amount of material removal during the cutting process, and the material removal rate of some aircraft structural parts is over 90%.

5. Thin wall, easy to produce processing deformation. There are a large number of thin-walled and deep cavity structures, which are typical weakly rigid structures.

6. The machining accuracy of five-axis machining of aerospace parts is high. Due to the need to achieve no-residue assembly, the requirements for seams and gaps on the process separation surface are very strict, and the five-axis machining and manufacturing precision of aerospace parts is required to be high.

7. It is difficult to select tools and cutting parameters. Since the development of the cutting tool industry cannot catch up with the development and application of new materials, and the lack of support from the processing and cutting database, how to reasonably select cutting tools and scientifically select processing parameters has become a difficult point in technology.

Linyang Hardware is a high-tech enterprise engaged in the machining of high-precision parts such as five-axis machining. Especially five-axis machining, widely used in various high-tech and precision industries, such as robot parts, drone parts, aviation parts, automation equipment parts, all workpieces can be customized according to customer needs, welcome to visit and call at any time.